Maximum attraction

22

May, 2017

Already standard in the food-industry, and of increasing importance in the building materials industry: in-mould labelling merges plastics packaging and labelling to a single, seamless, effective unit. This is a trend, quite impossible to ignore; whether in marketing or at the POS.

Recently in a hardware store in an Austrian city: a sales test. The buyer is tasked with choosing the best available white wall paint. As usual, there are several brands to choose from: all sold in identically formed plastic buckets. These are all very similar products, and without reading the small print, they are essentially indistinguishable from each other.

Motivational research over the past few decades offers a degree of insight into consumers’ shopping behaviour, providing an explanation for what happens on this day, on these shelves where paint is on display: in this particular hardware store. People listen to their gut – first and foremost. Buying decisions are directed primarily by emotions, meaning that the customer is most likely to reach for products that engage the buyer at this level. What this means in practice, is a paint bucket with the highly effective picture of an iceberg on it. A realistic, high quality representation of purest white.

Little effort for large savings

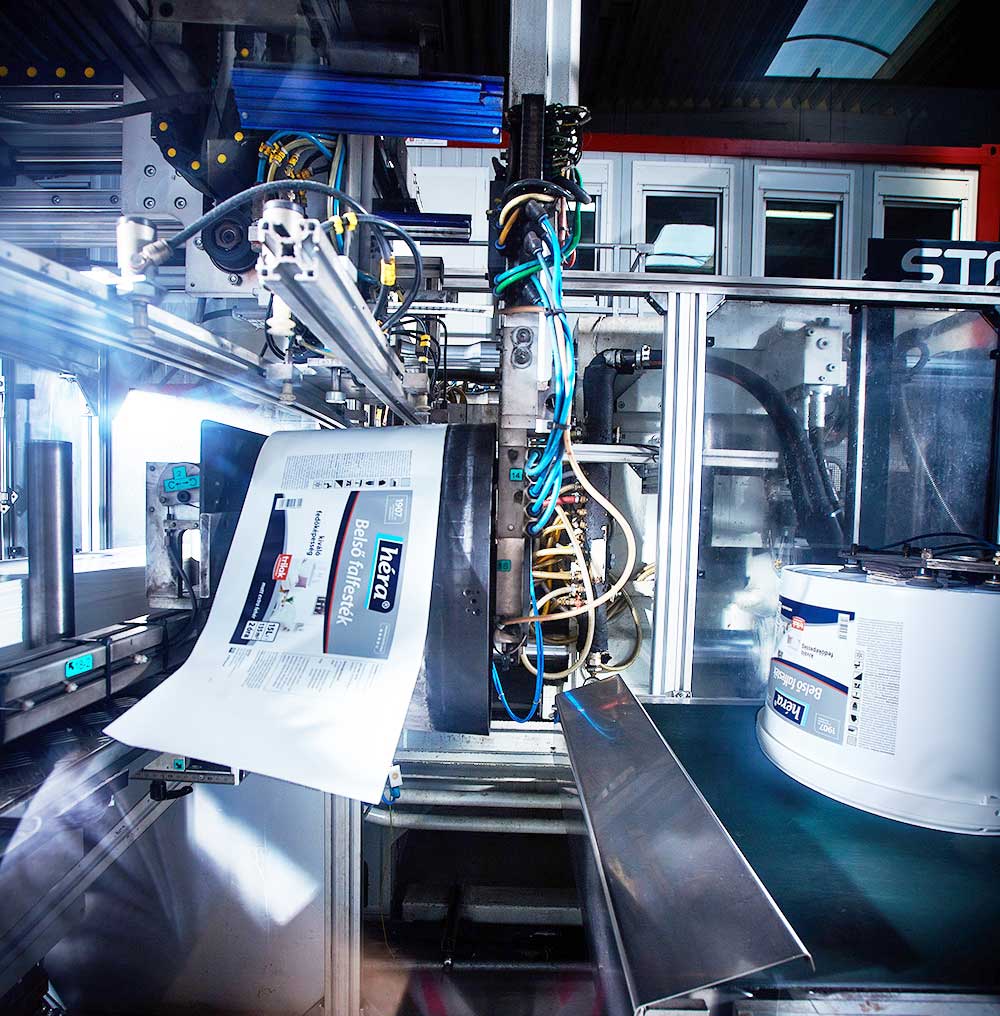

Said packaging model with its emotional picture is relatively new in the construction materials sector. This is quite different from the cosmetic or food industry, where in-mould labelling (IML) became commonplace years ago. IML is the process of seamlessly merging packaging and labelling. Yoghurt cups are a good example: outside they look fruity and they advertise the taste of the contents. The plastic itself becomes the lure: tempting the customer. In this way, it is easy to understand why most packaging design is following suit, industry by industry. Especially when the labelling process is minimised, and the costs are quickly made up. The market branding is strengthened, and in the shortened IML process, this occurs in line with the packaging: in one single, shared step. A pre-printed Polypropylene label is placed in the mould for the container, and becomes part of the article as the liquid plastic hardens. It is even possible to label all sides of a container in one work step. The creative advantage: with IML, there is hardly anything you can’t do. This opens up limitless imaginative possibilities. Not just for the visual medium, but also for touch, and even olfactory.

Inaccuracies, crooked placement or bubbles in the labels are finally a thing of the past with IML. Instead, bucket containers and canisters remain an optically appealing advert for the brand in question: even after intensive use.

IML also addresses recycling

At ALPLAindustrial, where IML has already been on offer for many years, pictures can be realised in brilliant print quality with up to eight colours. Quite naturally also in the photo-realistic look mentioned above. Because these labels are fused into the container, they cannot be removed, and as a result are “fake-proof”, and resistant to dirtying. In short, the professional and high quality presentation becomes an indicator of quality, and the most important criteria at the POS: as is clear from the test-buyer’s decision. IML ensures not only optical experiences such as full-surface pictures, on matt or gloss labels. It also addresses haptics. It is easy to produce flat, velvety or raw surfaces, perfectly tuned to the character of a particular product. The same goes for scents. Plastic packaging can also carry the aroma of strawberry, vanilla, and other pleasantly smelling fragrances. We have plenty of samples at ALPLAindustrial.

Last but not least, IML solves another question, central to the building materials sector – recycling. IML produced containers are 100% recyclable and highly environmentally friendly. Label and packaging are made up of materials with similar chemical properties. This means that there is nothing to stand in the way of reusing these valuable raw materials. Given the many advantages of in-mould labelling, you may well be interested and the IML-specialists at ALPLAindustrial are happy to help.