Digital

change

The connection between zeros and ones and buckets

A bucket will always be a bucket. But what it can do, how it is made and everything else its manufacturer achieves in doing so in the future has never been so open.

The unfortunate thing about buzzwords is that they soon begin to spread, you immediately feel affected by them, but often you don’t know exactly where. And that is how it is with digitalisation, too, which is ploughing its way through business fields – for some as a current and for others as a future scenario – or creating new ones. ‘Some’ refers to the retail trade, tourism industry and the world of media. Areas which have changed rapidly over the last two decades and now work in a completely different way. The ‘others’ are the manufacturers, the producers of actual things, including plastic packaging, for example, which has a core that cannot be digitised. And this core is also becoming smaller and smaller, because a large portion of it is possible in a different way. More networking, greater intelligence, with new standards for efficiency, i.e., digital. This is why digitalisation is a big topic for ALPLAindustrial. A topic we have explored, filtered and addressed intensively in recent years in order to take advantage of the heightened pace in the competitive production environment. Being open-minded with regard to changes. With an ear for the marketplace and an eye for developments. Keenly observing and finding out what is important for the customer and in turn for us. Human factors, therefore, continue to be crucial for the fabrication of the future. Everyone at ALPLAindustrial is aware of this. This is why we embedded lean management in our company some time ago. You need inquisitive, open-minded employees who, above all, are able to “think beyond the pack” and see the interrelations. This applies to everyone, whether you are a machine adjuster, a warehouse handler or a member of management. Especially in times of digitalisation. It is merely an impulse to make things better. Not only the plastic packaging but also all the services associated with it.

Digitalisation doesn’t stop at packaging producers.

ALPLAindustrial is fully prepared.

The way taken by ALPLAindustrial features three interconnected areas. One of them is the product, or the question of which additional benefits it can be equipped with in the future. The trend in packaging is towards individualised solutions. The possibility of a personal design, in small series or as a unique item, realised with the advantages of automation. The added value of a container can also be in it being identifiable at any time and wherever it is. In other words, traceability. Or using codes on the packaging to call up content. Whatever it is: the contours of a packaging item no longer have to represent their limits. The technological opportunities offered by digitalisation open up new perspectives.

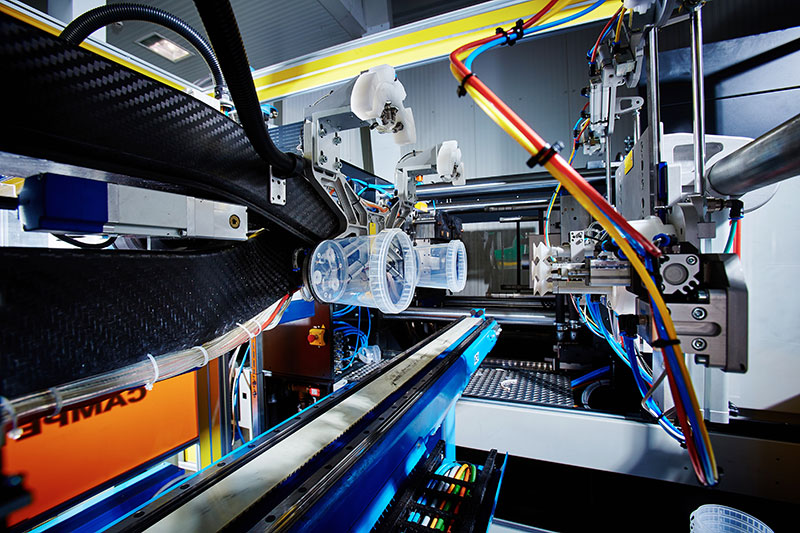

Which leads us automatically to the next point – production. Strong IT support for all processes is a fundamental requirement, but there is more to it. Meeting the individual customer requirements in a flexible and economic way calls for a smooth production chain from the manufacturer. Here it is practical that ALPLAindustrial not only produces buckets and canisters but also machine data. Or to put it differently: experience on what makes things run smoothly – or the fine tuning which is still required here and there in the process. ALPLAindustrial is also planning a digital twin of the real facility at some point for this tuning. This will make it possible to try out various possibilities on the computer to optimise production even further. The company has already invested a considerable amount in this area. What used to be two-stage production is now only a single stage. Instead of producing and printing packaging, this now takes place in a single step thanks to in-mould labelling. The labels for it are bought in. Another concrete result of the changed digital world of fabrication – thinking carefully about where it still makes sense to do things yourself or whether it is better to have deeper cooperation. Networking. With suppliers, know-how workshops, and also by accommodating the wishes of customers. The latter applies above all to warehousing and the supply chain – but not only.

The question of the business model thus forms the third area, which ALPLAindustrial considers to be significant for its digital strategy. Do we want to continue to be a pure producer of packaging or create specific added value which goes beyond it? In times in which value chains throughout the world are in a disruptive state, the only certainty is change. Although the focus on the core business at ALPLAindustrial will not shift, the openness for new developments will also remain a focal point. Will it one day be possible to integrate a chip in injection moulding? What could it then contain so that the packaging provides added value for the end customer? When will intelligent shelf systems which manage their own stock themselves and send out digital notifications to suppliers when stocks are low be worthwhile? These are all questions which do not affect ALPLAindustrial directly but still keep us busy nevertheless. Because although digitalisation makes many things possible, there is one thing you cannot do with it, and that is ignore it.